Today, many of the ways we heat buildings around the world – such as homes, offices, schools and factories – still rely largely on fossil fuels, particularly natural gas. It haslong been clear that this leads to large amounts of greenhouse gas emissions – and the current global energy crisis is a sharp reminder of the urgency of moving to more affordable, reliable and cleaner ways of heating buildings. In this context, heat pumps, which can efficiently provide heating to buildings and industry, are the key technology to make heating more secure and sustainable. They are quickly becoming more cost competitive, drawing interest from a growing number of governments, businesses and consumers across the globe. Until now, though, there has not been a comprehensive global study of the state of play of heat pumps – and their future role in our energy systems. This World Energy Outlook special report aims to fill that gap. Our in‐depth analysis finds that policy plans announced so far by governments globally point to a large expansion of the use of heat pumps, which will have a clear impact on the use of gas, oil and coal for heating. Heat pumps have the potential to reduce global carbon dioxide emissions by at least 500 million tonnes in 2030. For Europe, they are a vital tool to cut reliance on Russian gas,since they can lower Europe’slargestsource of gas demand – heating in buildings – by at least 21 billion cubic metres in 2030.

Introduction This chapter assesses the outlook for heat pump installations and their impact on the energy mix for heating in buildings and industry, drawing on the projections of the system‐wide energy scenarios depicted in the latest edition of the World Energy Outlook (WEO), released in October 2022 (IEA, 2022a). Emphasis is given here to the Announced Pledges Scenario (APS), which assumes that governments around the world meet all announced energy‐ and climate‐related commitments in full and on time. This is contrasted throughout the report with the Stated Policies Scenario (STEPS), which describes how the global energy system would evolve under the policies already in place today, provided they are backed by concrete implementation plans. These comparisons are intended to highlight where additional efforts are required to accelerate heat pump deployment. In some cases, the APS projections are also compared with the Net Zero Emissions by 2050 (NZE) Scenario, which represents a pathway to reduce energy emissionsto zero on a net basis by 2050 in order to stabilise global average temperatures at 1.5 °C above pre‐industrial levels. More detail about the scenarios and the projections can be found in WEO 2022. A heat pump uses technology similar to that found in a refrigerator or an air conditioner. It extracts heat1 from a source, such as the surrounding air, geothermal energy stored in the ground, or nearby sources of water or waste heat from a factory. It then amplifies and transfers the heat to where it is needed (Figure 1.1). Because most of the heat is transferred rather than generated, heat pumps are far more efficient than conventional heating technologies such as boilers or electric heaters and can be cheaper to run. The output of energy in the form of heat is normally several times greater than that required to power the heat pump, normally in the form of electricity. For example, the coefficient of performance (COP) for a typical household heat pump is around four, i.e. the energy output is four times greater than the electrical energy used to run it. This makes current models 3‐5 times more energy efficient than gas boilers. Heat pumps can be combined with other heating systems, commonly gas, in hybrid configurations.

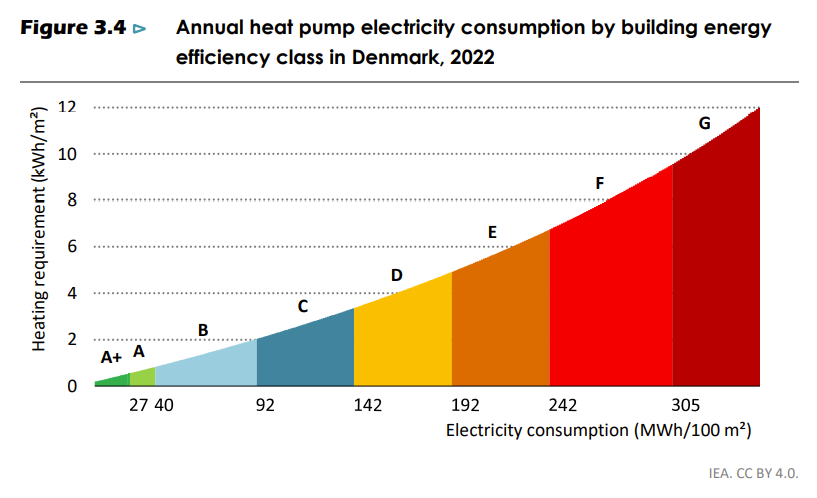

The efficiency of a heat pump depends critically on the source of the heat. In winter, the ground and external watersources typically remain warmer than the ambient air,so ground‐ source and water‐source heat pumps consume less electricity than air‐source ones, yielding a higher COP. This is particularly the case in cold climates where defrosting the outside components of air‐source heat pumps can consume additional energy. However, ground‐ source heat pumps are more expensive to install, as they require an underground heat exchanger – a deep vertical borehole or a large network of pipes buried at least one metre below the surface of the ground. Connecting a water‐source heat pump to a nearby river, groundwater or wastewater can also be costly.

Heating needs Heating currently represents a sizeable share of global energy consumption and a major source of CO2 emissions. Global energy demand for space and water heating amounted to 62 exajoules (EJ) in 2021, accounting for around half of energy consumption in buildings and directly emitting 2.5 gigatonnes (Gt) of CO2 – roughly 80% of direct buildings emissions. This moves up to 4 Gt of CO2 when considering indirect emissions from electricity and district heating.

The level of energy demand varies substantially by household within and across countries and regions, mainly according to climate, household size, living space, the degree to which buildings are well‐insulated, and the type and quality of heating equipment (Figure 1.2). Around 70% of total heating needs are for space heating and the rest for hot water. The energy mix for heating also varies. Natural gas is the leading form of energy for heating in buildings, meeting 42% of heating energy demand globally. One sixth of global natural gas demand is for heating in buildings—in the European Union this number moves up to one third. Oil follows next with 15%, then electricity at 15%, and district heating – concentrated in China, Northern and Eastern Europe, and Central Asia – at 11%. The direct use of biomass and coal make up the difference. The fuel mix for heating differs substantially across major heating regions, though gas dominates everywhere except East Asia.

Industrial heat pumps There is considerable potential for electric heat pumps to provide process heat for industry. Because of the complexity of industrial processes, heat pumps generally need to be tailored to specific applications. In contrast to those used in buildings, industrial heat pumps typically rely on higher input temperatures, asthe required output temperatures are also significantly higher. Today, industrial heat pumps are mainly used for low‐temperature processes below 100 °C, notably in the paper, food and chemicals industries (Table 1.2). However, output temperatures of up to 150 °C can already be achieved if waste heat of about 100 °C is available as input. For temperatures between 150 °C and 200 °C, heat pumps need special refrigerants and compressors, for which technologies are still in an early prototype stage.

Industrial heat pumps can be very efficient, with a COP of more than three, when the temperature lift, i.e. the difference between the input and output temperatures, is in the 30‐50 °C range. For higher temperature lifts, the COP is generally lower, though a heat pump can be configured in a way that limits the loss of efficiency, such as by incorporating intermediate heat exchangers or cascaded cycles(whereby the pump operates astwo single‐ stage cycles coupled together by a cascade heat exchanger). However, the costs of such heat pump systems are usually significantly higher.

With today’s F‐gas refrigerants and full leakage, heat pumps still reduce greenhouse gas emissions by at least 20% compared with a high‐efficiency gas boiler, even when running on emissions‐intensive electricity. In regions accounting for 70% of world energy consumption, the emissions savings are above 45% and reach 80% in countries with cleaner electricity mixes. These values can be improved by 10 percentage points, respectively, with alternative refrigerants. The large variation is mainly due to differences in the emissions intensity of electricity generation rather than refrigerant choice. Figure 2.7 illustrates emissions savings in four countries based on their climate conditions and emissions intensity of electricity production.

If F‐gas refrigerants continue to be used in the same way, by 2030 in the NZE Scenario, the global heat pump stock will bank nearly 740 Mt CO2 equivalent of greenhouse gas emissions – about twice the total annual greenhouse gas emissions of Australia. Even if today’s best practices in maintenance and recycling were applied worldwide, only one‐third of these emissions would be prevented, making it harder to limit the global temperature rise to 1.5 °C.

The running costs of a heat pump are also affected by how well it is operated and maintained. It is essential that the owner of a heat pump isinformed about correct handling and the need for thorough maintenance by qualified technicians so that they operate efficiently and at optimal cost throughout their lifetime. Air‐source heat pumps can become clogged with dirt over time, leading to increased electricity consumption and premature wearing of the unit, as well as noisier operation. Refrigerants also tend to leak out over time, which reduces efficiency, as well as contributing to climate change . Refrigerant leakage warning systems are currently commercially available for large heat pumps; a roll‐out to residential systems could help users identify the reason for loss in performance and avoid the emission of refrigerant gas.

Non‐cost hurdles to consumer adoption In addition to cost, there are a range of other hurdles to the adoption by consumers of heat pumps, notably restrictions relating to heat pump installation, a lack of information about the benefits of heat pumps, and split incentives between building owners and tenants. While these barriers are less concrete in nature than costs, they contribute significantly to the reticence of many consumers to opt for a heat pump over other heating systems. A failure to take action to address them could deter large numbers of consumers and hold back deployment of the technology. Many countries have developed programmes to address some of the barriers. Further efforts are needed to strengthen them and apply them more widely.

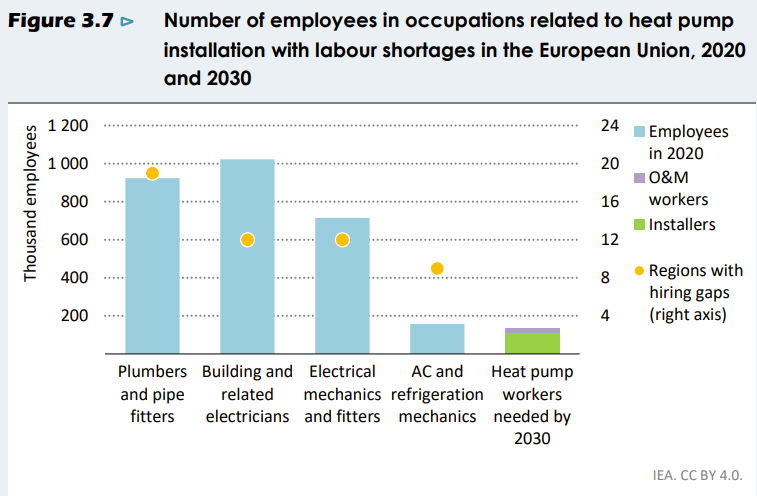

The REPowerEU targets for heat pumps, reflected in the APS, call for an increase in the number of trained heat pump installers from around 40 000 in 2019 to 110 000 by 2030. Certification is mandatory across all EU countries for heat pump installations that require refrigerant handling by the installer, which is the case for most systems, except self‐ contained systems like a monobloc. With increasing restrictions on F‐Gas refrigerant usage in line with the Kigali Amendment, the required certification may pass from handling of F‐Gases to handling of flammable material. However, for the majority of installations, requirements for training and certification of installers vary between countries, despite the requirement for mutually recognised certification under the Renewable Energy Directive. Given the enormous differences in the maturity of the heat pump market across countries, collaboration between them on heat pump installer training and transfer of best‐practice know‐how could help ensure efficient and high‐ quality installations and achieve the REPowerEU targets.

Source:IEA

You must be logged in to post a comment.