Introduction

Rationale, aim, and scope

According to SolarPower Europe’s market data, India has over 45 GW of installed solar capacity on its

territory, making it the fifth largest solar Photovoltaic (PV) nation in the world. This is supported by a

project development pipeline of 53.6 GW and a further 24.1 GW of projects tendered or pending

auction (International Centre for Sustainable Carbon, 2021). By 2025, solar installations are set to nearly treble in size, reaching 133 GW, according to Solar Power Europe’s business-as-usual scenario.

These rapid growth projections highlight the extent of India’s renewable energy ambitions, and the

government has set a target of installing 500 GW non-fossil energy capacity by 2030, meeting 50%

of energy requirements from renewable energy by 2030, and achieving Net Zero by 2070. Key to the

growth of the Indian solar market over this period will be showing that solar PV is a reliable and

flexible technology that can answer India’s energy demands. This means ensuring that PV projects are

meticulously planned, and power plants are built to the highest possible standards, using the best

available equipment. Engineering, procurement, and construction (EPC) service providers will play

a hugely important role in achieving this. The cost of PV energy is a function of CAPEX, OPEX, finance, and the amount of energy generated by a PV system. There is relentless competition in the marketplace, which is mostly played out in terms of cost. The four elements above are often seen as independent of one another and are optimised separately. This may not be ideal as quality assurance is the link between these elements; CAPEX savings may lead to higher OPEX, or reduced energy generation. These Guidelines can help minimise risks resulting from this siloed approach to optimisation.

Definitions

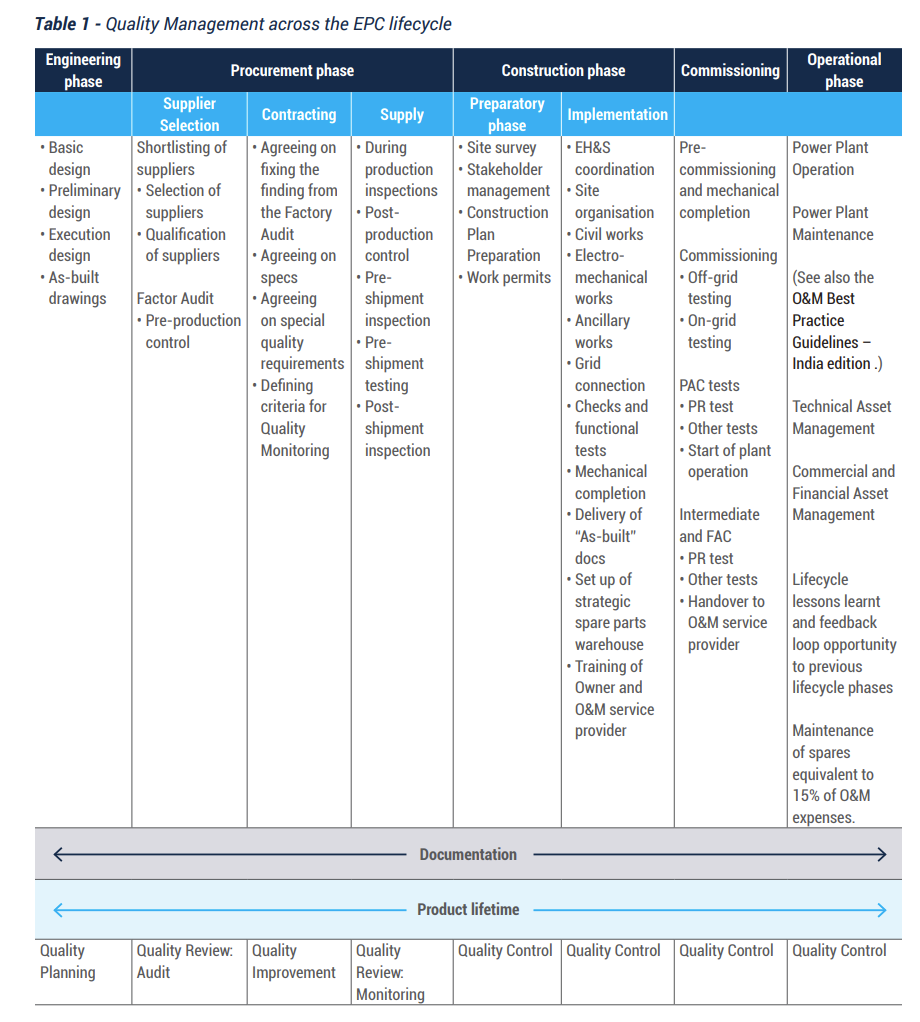

Lifecycle of EPC Quality Management

A solar plant is a structure with many components. It is comprised of rows of solar PV panels mounted

on structures, connected in series and supported on foundations usually composed of partially

embedded steel pipes. Rows of solar panels are mounted on the racking and are connected through

electric wires which take DC power generated by the panels through combiner boxes to inverter houses where inverters convert it to AC power. This AC power is passed through step up transformers

that raise the voltage to a suitable level for the main utility lines into which it is fed via a switching control and metering system. The quality of the components described above, their installation, and their maintenance are all vital to ensuring the system operates efficiently. This chapter covers the key aspects of quality assurance in the EPC phase of an asset’s lifecycle. Quality – if not set by clear criteria and measurements – is a perceptual, conditional, and somewhat subjective attribute and may be understood differently by different people. Ingeneral, it can be defined as a commitment to customers in the market or as fitness for intended use, in other words, how well the product performs its intended function. Quality also takes into account the reduction of harm that a product may cause to the environment

or human society. By applying Quality Management (QM) an organisation seeks to ensure that this goal

is achieved.

From Site Selection, Engineering, Procurement, Delivery, Construction, Operation and even the End-of-Life Phase, QM must pervade the project management approach. Moreover, QM actions should always be flanked by good documentation.

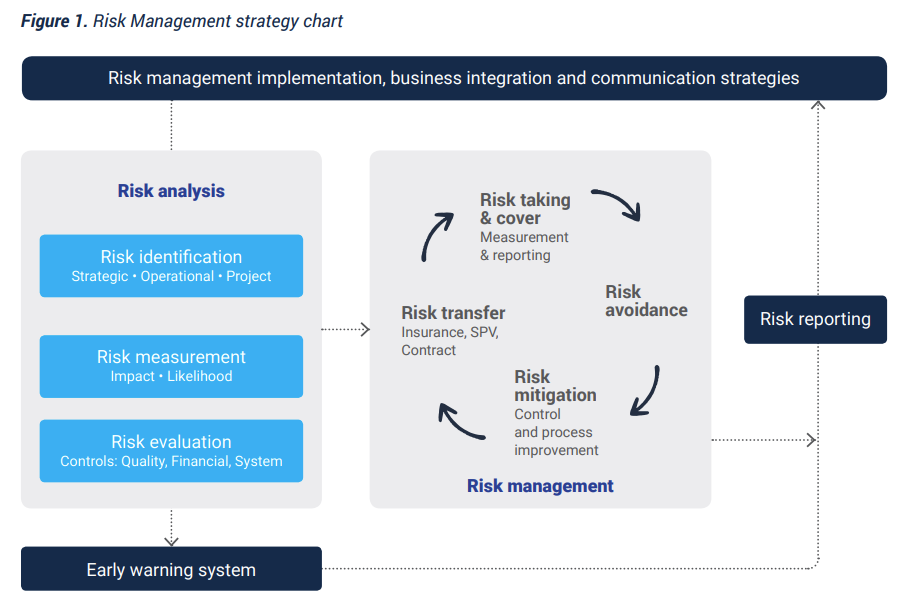

Risk Management during the EPC phase

The term “risk” is often characterised by reference to potential events and consequences or a combination of these. It is often expressed in terms of a combination of the consequences of an event

(including changes in circumstances) and the associated likelihood of occurrence. ISO guide 73

Risk Management defines risk more simply as “effect of uncertainty on objectives”. It is to be noted that

the word “effect” can refer to positive and negative deviations from previous expectations. The term “objectives” can have different aspects (financial, health and safety, environmental, etc.) and can apply at different levels (strategic, organisational, project, product, and process). “Uncertainty” is the state, even partial, of a lack of information related to understanding or knowledge of an event, its consequence or likelihood.

processes to another party via a contract, buying an insurance plan that provides cover or setting up a

purpose specific limited liability company (otherwise known as an SPV). There may be some residual risks that cannot be fully mitigated against or transferred. These must be controlled by proper measurement and by effective reporting structures to ensure that exposure to them remains within manageable limits. The following subchapters outline several broad categories of risk. Risk-mitigation and transfer methods are not discussed in great detail as this would go beyond the scope of this document. Whilst the risks identified in this chapter are present throughout a project’s lifecycle, they are helpfully contextualised within the EPC phase. This helps give both EPC service providers and Asset Owners alike an insight into each other’s concerns.

Environment, Health & Safety

Environment, Health & Safety (EH&S) are critically important during the EPC phase of a solar projects.

In India, the main legal requirements for ensuring occupational health & safety come from the Technical

Standards for Construction of Electrical Plants and Electric Lines, 2010, and the CEA-Measures Relating to safety and Electric Supply, 2010. These can be combined with internationally accepted standards, such as the IFC Performance Standards and the Equator Principles, to make sure that solar projects do not negatively impact the environment and ensure a healthy and safe workplace. Furthermore, international financial institutions also use EH&S and social criteria when assessing projects. This chapter proposes an overview of EH&S best practices.

Personnel & training

One of the challenges for EPC service providers is to manage the expectations of all parties involved

in the process, during a relatively short period of time. These stakeholders include the Asset Owner

(or project developer), investors (if separate to the project developer), insurance companies, operators,

maintenance companies, utilities, (surrounding) landowners, suppliers, advisors and more. There

are also the EPC service provider’s own employees, and subcontractors for mechanical and/or electrical

installation. Personnel must deal with a range of work, such as selecting modules, creating electrical wiring diagrams with an awareness of local site regulations, civil and construction work, which for example can include earth or mechanical work. Other examples involve supply chain and logistics, including transportation or restrictions on work, access to sites, manpower in general, and local restrictions on travel and accommodation.

Transition from project development to EPC

Project requirements are generally set up during the development phase (which precedes the EPC phase). They are mainly regulated under project development agreements. These are executed between the Special Purpose Vehicle (SPV), as the Owner of the project (or the Asset Owner, when the SPV has not been established yet), and the local developer who is in the early development phase conducting the initial engineering activities including the setup of the layout. In addition to technical activities, the

developer is also responsible for filing all the requests for the necessary authorisations and construction permits with the competent public administrations. For these reasons, the role of the EPC service provider is marginal in the early development stage. This is confirmed by the fact that the layout and the other prescriptions to be met are generally outside the EPC service provider’s scope of work.

Engineering

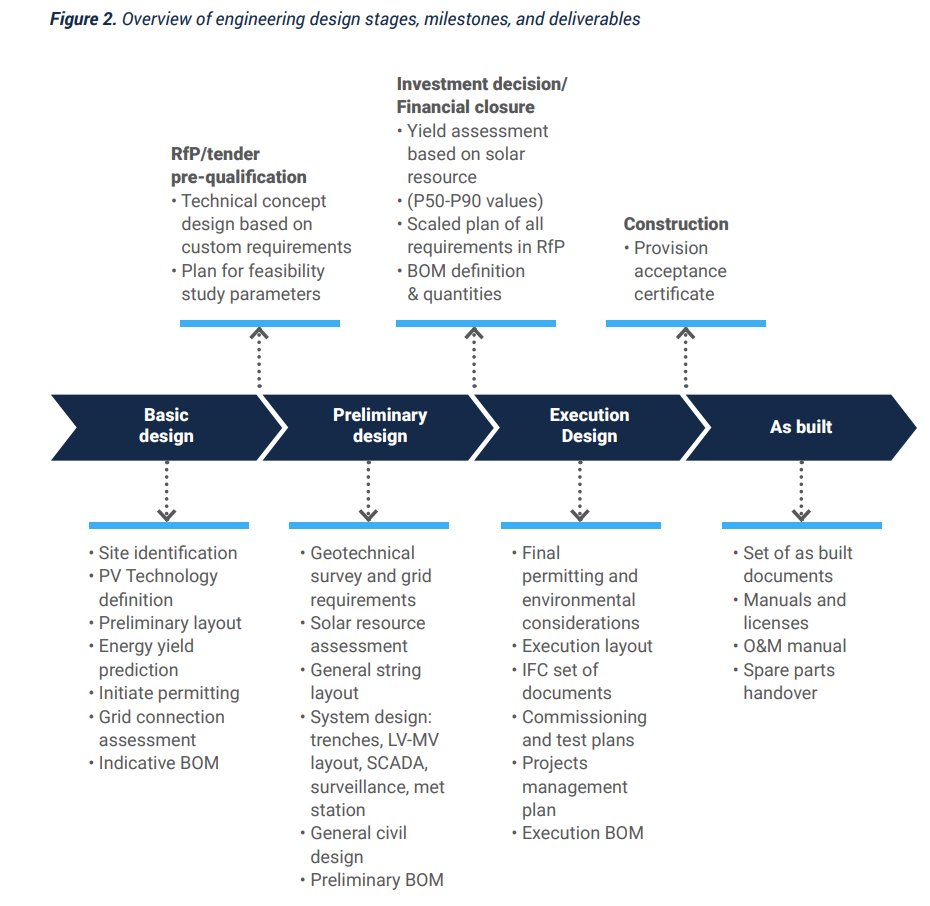

The engineering design and modelling of a PV power plant is a crucial element of the EPC lifecycle,

as it guides the whole process of EPC, from conceptualisation to investment decisions and to the actual construction of the solar power plant. It is also a highly iterative process in which inputs from all the main stakeholders are considered, to generate the most suitable project plan for a successful and

efficient PV plant.

Starting off as a basic technical concept, the engineering design is itself a process that evolves

and is constantly refined as the project development advances. It evolves into a detailed execution design blueprint issued for construction. Once construction and commissioning are completed, a detailed set of “as built” documents is handed over to the O&M service provider.

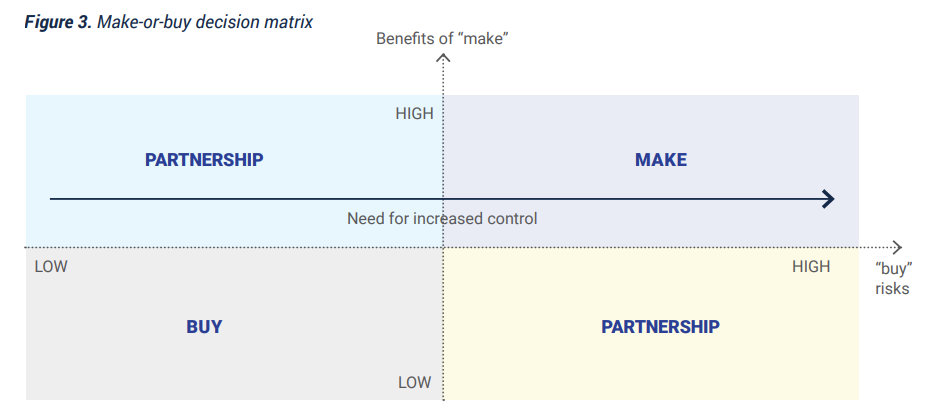

Procurement

The Procurement phase covers purchasing components such as PV modules and inverters, as well as identifying and mitigating risks. It involves supplier selection and onboarding, and conducting

inspections, and tests to qualify materials to be used in construction throughout the procurement

process. This chapter will help stakeholders to identify risks in the procurement process of components (such as PV modules, inverters) and to mitigate them through suitable inspection, testing and qualification mechanisms for individual projects. The procedures shall be underlined with definitions of acceptance level and criteria. It is important to ensure that all the components of a PV system conform to the contracts that they are procured under. This is particularly important when it comes to the bill of materials for PV modules. Here, each material, and their variations and combinations, needs to be agreed with the supplier (manufacturer) and documented to carry out an effective assessment of components at a project level.

Frequently, developers are mandated to release procurement tenders for goods needed for the EPC

phase. Government agencies or organizations also release tenders for the supply of goods, services,

EPC or turnkey solutions for operational needs or for new requirements in lots. The bidder that offers

the lowest price is awarded the lots that they made offers for first (referred to as the bucket-fill method). This makes the procurement business competitive and transparent. EPC service providers are required to adhere to the prices quoted in their bids.

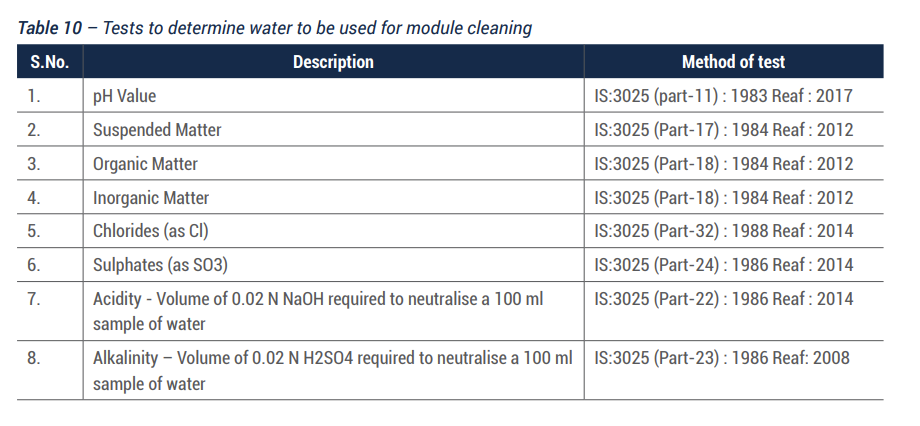

Construction

This chapter describes the main activities, concerns, and requirements to be met during the construction phase of a PV plant. In this phase, the solar power plant is installed based on installation manuals

provided by suppliers to assure the proper storage, handling and installation of mounting systems,

PV modules, inverters, transformers, cabling, monitoring system/sensors and other balance of system components. It also ensures the quality of the installation as well as the long-term stability of the PV system. A proper schedule and preparation of several activities around the construction are important and should preferably be organised according to common project management techniques. This includes clear definition of objectives, activities, and responsibilities (who does what?), time plans and milestones (when?), cost planning, and quality assurance. To achieve this, an effective and efficient

communication, documentation and reporting flow between the Asset Owner, the EPC service provider

and the subcontractors is necessary. This will help encourage accountability, potential construction

defects are promptly identified, high standards upheld, and monitoring the EPC service provider’s performance is easier.

System Commissioning

System commissioning is one of the most important stages of the EPC service provider’s work as it

closes the construction period and prepares the PV plant for commercial operation. This crucial step of the project includes performance and reliability tests. These make sure that the PV plant is built according to the international standards and industry best practices, and that it complies with

the requirements as agreed with the Owner, grid specifications and guaranteed performance levels.

Tests are undertaken for all individual components from checking that components function to more

detailed measurements and verifications of the overall system. Successful commissioning and timely achievement of the Commercial Operation Date (COD) is linked to the release of a milestone payment as defined in the contract as well as the release of the performance bond. It is, therefore, very important that the contract clearly describes the requirements, criteria, documentation, and reporting required to complete the EPC service provider’s scope of work and handover to the Asset Owner and the O&M service provider’s team.

Handover to O&M service provider

This chapter describes the procedures for properly transferring the O&M activities of a PV plant from

the EPC to the O&M service provider. After the FAC, when the Asset Owner takes over the full contractual responsibility for the plant operation, it is industry practice to hand over the long-term O&M activities to specialised third-party O&M service providers. These specialised service providers are organised to provide best in class O&M activities. Their technical departments are designed to provide high level remote monitoring of failures and performances, timely on-site maintenance activities, project management services, and strategic spare parts management etc. (For more information and best

practices, please refer to SolarPower Europe’s O&M Best Practice Guidelines – India edition.)

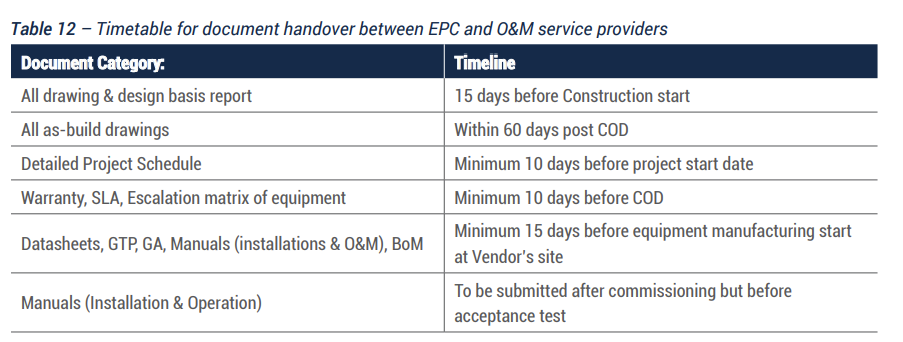

The EPC service provider shall provide the following documents as per the timelines mentioned below.

A detailed checklist of all the documents to be submitted by the contractor shall be mutually finalised.

Key Performance Indicators

Project performance KPIs During the construction phase, the performance of the project should be tracked closely. There are available project management standards for this, such as ISO 21500, or publications of associations like the Project Management Institute (PMI). In principle, project management tracks deadlines, budget, and quality, to achieve planned results. There exist multiple KPIs for project performance. Here we focus on those which track the three essential elements of the ‘project management triangle’: (1) time, (2) budget, (3) quality. To achieve customer satisfaction, the planned goals concerning these elements have to be respected. The sections below discuss KPIs related to these aspects in more detail.

Contractual framework

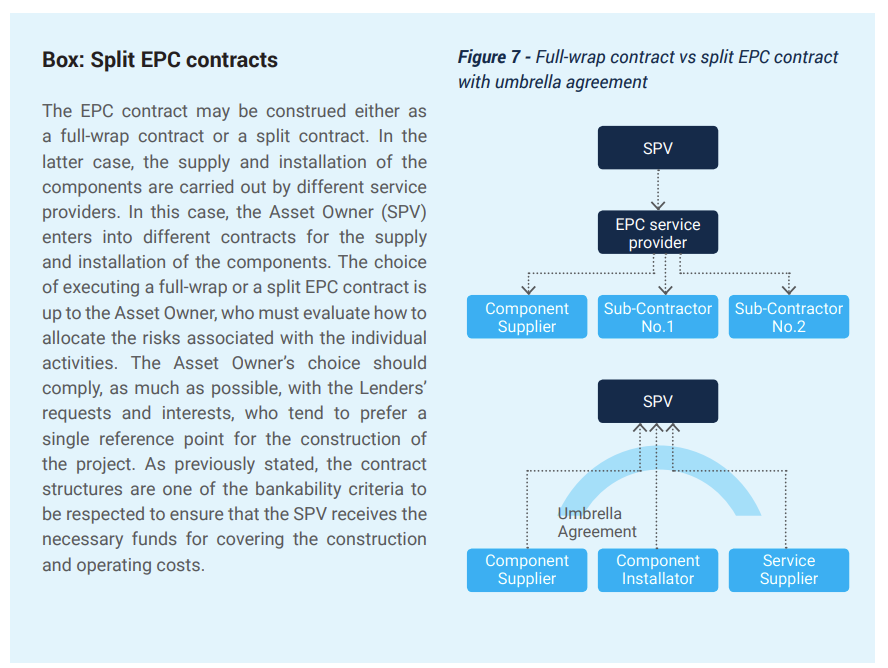

This chapter describes the best practice for a “full-wrap” EPC contract, under which the EPC service

provider undertakes to build and deliver the plant in compliance with the agreed time-schedule. The

EPC service provider also manages the supply of the necessary equipment, and all the necessary

ancillary works and activities. For other approaches such as “split contracts”, see the box on Split EPC

contracts. Under a standard EPC contract, the service provider will typically have to meet a precise deadline to reach the Commercial Operation Date (COD). Setting this deadline right is particularly crucial when the plant is willing to apply for feed-in tariffs (considering that, quite often, this is dependent on reaching COD within a certain date) or has to meet contractual deadlines within the terms of a corporate power purchase agreement (which might result in liquidated damages being payable to the off-takers of the Power Purchase Agreement).

Ownership and transfer of risk

The Asset Owner acquires full title on the rights and guarantees over the components to be installed (except the mounting system, panels, and inverters) upon delivery to the site. For the main components (PV modules, mounting system, transformers and inverters), the timing of transfer is the issuance of the PAC, as they must be installed and tested by the EPC service provider. Until the PAC issuance date, the EPC service provider retains full title on the main components by virtue of its role as installer and operator of the plant.

Source:SOLAR EUROPE

You must be logged in to post a comment.